Stainless Steel 409 409M 410

Stainless Steel 409 409M 410

"The 400 series group of stainless steels has an 11 percent chromium and 1-percent manganese increase, above the 300 series group. The 400 series is susceptible to rust and corrosion under some conditions. Heat-treating will harden the 400 series. The 400 series of stainless steels have higher carbon content, giving it a martensitic crystalline structure. This provides high strength and high wear resistance. Martensitic stainless steels aren’t as corrosion resistant as the austenitic types.

| 409 Stainless Steel

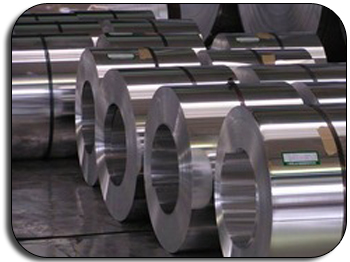

Rajasthan Steel Centre are inventory now includes Alloy 409 (UNS S40900) in sheet, sheet coil, plate, round bar, processed flat bar and tubular products. General PropertiesAlloy 409 is a general purpose, chromium, titanium stabilized, ferritic stainless steel whose primary application is automotive exhaust systems. It contains 11% chromium which is the minimum amount for the formation of the passive surface film which gives stainless steels their corrosion resistance. |  |

Although Alloy 409 is designed principally for the automotive exhaust industry, it has been successfully used in other industrial applications as well. Some examples of applications that call for Alloy 409 include:

- Automotive exhaust systems

- Catalytic converters

- Mufflers

- Tailpipes

- Farm equipment

- Structural support and hangers

- Transformer cases

- Furnace components

- Heat exchanger tubing

- ASTM/ASME: UNS S40900

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

Chemical composition:

| C | Mn | Si | P | S | Cr | Ni | Ti | |

|---|---|---|---|---|---|---|---|---|

| 409 | max:0.08 | max:1.0 | max:1.0 | max:0.045 | max: 0.045 | min: 10.5 max: 11.75 | max: 0.5 | min: 0.48 max: 0.75 |

Mechanical Properties:

| Grade | Tensile Strength MPa (min) | Yield Strength 0.2% MPa(min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 409 | 380 | 207 | 20 | 207 | 95 |

Physical Properties

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|

| at 68°F: 0.280 | 9.4 at 212°F | 28.3 at 68°F | 29 | 5.84 at 32 – 212°F | 0.114 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 6.60 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 6.86 at 32 – 1500°F |

|

Rajasthan Steel Centre aare Manufacturers, Supplier and Exporters of Stainless Steel 409M Stainless Steel and Rods that is Fabricated From High Quality Raw Materials. 409M Stainless Steel is a low carbon austenitic alloy. 409M Stainless Steel other sizes can be made available on request. |  |

AISI 304L, UNS S30403, Werks

- Dimensions.

Pipe sizes normally furnished are NPS 14 to NPS 30 with extra light (Schedule 5S) and light (Schedule 10S) wall thickness.

- Minimum Wall Thickness.

At any point this must not be more than 0.018 in (0.46 mm) under the specified wall thickness.

- Outside Diameter.

For wall thicknesses <0.188 in (4.8 mm) OD tolerance is ±20%. For wall thicknesses >0.188 in (4.8 mm) OD tolerance is ±40%.

- Out-of-Roundness.

The difference between maximum and minimum OD must be <1.5% of the specified OD.

- Straightness.

Deviation from 10 ft (3 m) straight edge is < 3/16 in (4.8 mm).

- Cut Lengths.

Unless otherwise specified, pipes NPS 22 are not less than 5 ft. Circumferential welding of two or more lengths may be specified.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 409M | 0.03 max | 0.81.2 max | 0.40.75 max | 0.030 max | 0.030 max | 11 – 12 | - | 1.5 Max | - |

Mechanical & Physical Properties:

| Hardness ( BHN ) | 187 |

| Hardness ( RB ) | 90 |

| Tensile Strength | 430 |

| Yield Strength (0.2%Offset) | 275 |

| Elongation | 20 % |

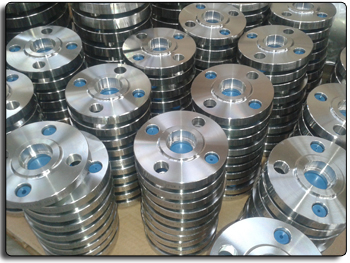

| 410 Stainless Steel Rajasthan Steel Centre inventory now includes Alloy 410 (UNS S41000) in sheet, sheet coil, plate, round bar, processed flat bar and tubular products. General PropertiesAlloy 410 is the basic, general purpose martensitic stainless steel that is used for highly stressed parts and provides good corrosion resistance plus high strength and hardness. |  |

Specifications: UNS S30400 / S30403

Applications:Applications requiring moderate corrosion resistance and high mechanical properties are ideal for Alloy 410. Examples of applications that frequently used Alloy 410 include:

- Cutlery

- Steam and gas turbine blades

- Kitchen utensils

- Bolts, nuts, screws

- Pump and valve parts and shafts

- Mine ladder rugs

- Dental and surgical instruments

- Nozzles

- Hardened steel balls and seats for oil well pumps

Standards:

- ASTM/ASME: UNS S41000

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

| C | Mn | Si | P | S | Cr | Ni | |

|---|---|---|---|---|---|---|---|

| 410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 |

0.50 max |

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410 | 65 (450) | 30 (205) | 20 | 217 | 96 |

| Heat Treatment | T410 (0.14%C) Hardened 1800°F (982°C) | ||

|---|---|---|---|

| Rockwell Hardness | 0.2% YS, Ksi (MPa) | UTS, Ksi (MPa) | |

| Annealed* | 81 HRB | 45.4 (313) | 80.4 (554) |

| Hardened & Tempered 400°F (204°C) | 43 HRC | 156.1 (1076) | 202.9 (1399) |

| Hardened & Tempered 550°F (288°C) | 40 HRC | 148.3 (1022) | 187.0 (1289) |

| Hardened & Tempered 600°F (316°C) | 40 HRC | 148.8 (1026) | 186.1 (1283) |

| Hardened & Tempered 800°F (427°C) | 41 HRC | 132.9 (916) | 188.5 (1300) |

| Hardened & Tempered 900°F (482°C) | 41 HRC | 122.6 (845) | 154.3 (1063) |

| Hardened & Tempered 1000°F (538°C) | 35 HRC | 127.9 (882) | 154.3 (1063) |

| Hardened & Tempered 1200°F (649°C) | 98 HRB | 85.5 (589) | 111.2 (767) |

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|

| at 68°F: 0.276 | 14.4 at 212°F | 56 at 68°F | 29 | 5.90 at 68 – 392°F | 0.11 at 68°F to 212°F | 2700 to 2790 |

| 6.5 at 68 – 1112°F |